The American Bureau of Shipping (ABS) has provided certification services to the marine and offshore industries for more than 150 years. The ABS was established in New York in 1862; its primary role was to certify ship captains. Almost ten years after its establishment, the ABS rolled out its first set of standards; these standards were published for wooden ships and came from a need to regulate the marine industry.

Revisions to these standards were continuously made as vessel materials improved and other materials became obsolete- from wood to iron to steel. Today, as technology continues to advance rapidly, revisions are made and published on an annual basis to ensure that the quality and standards coincide with any changes in the technology or the maritime industry.

The ABS also uses International Maritime Organization (IMO) standards and primarily works with commercial vessels in the United States. Its mission is to “promote the security of life and property, and preserve the natural environment.” Their guidelines establish appropriate structures, vessels, materials, products, and technology requirements.

Over 100 governments have recognized the American Bureau of Shipping’s expertise in marine performance. Services offered by the bureau include classification, approval and verification, company and ship audits, global marine, global offshore, global government, sustainability and decarbonization, digital solutions, cybersecurity, and maritime safety.

Who needs approval from the American Bureau of Shipping?

As a provider of regulatory services for the marine industry, the ABS organization sets standards for vessels like tankers, containerships, bulk carriers, gas carriers, shuttle tankers, yachts, and inland vessels, provides condition assessment programs, and provides solutions and strategies for sustainability in the marine industry.

Equipment or materials installed on ABS-class vessels should meet the organization’s standards and have certifications. Many suppliers and companies that produce marine equipment must go through a certification process so that classified vessels can use and install their equipment and materials.

The American Bureau of Shipping organization currently operates its classification standards under 200 rules and guides. These rules combine standards from naval architecture, marine engineering, and related fields.

Companies who apply for ABS approval and certification can do so under several categories depending on their needs.

Seatronx applied for ABS Type approval for their SRT/PHT series marine display, and Type Approval consists of:

ABS Type Approval

Type approval simplifies the acceptance of products and equipment on ABS-class vessels, units, and other marine applications. ABS can offer the following, depending on the manufacturing process:

- For batch-produced products, ABS can provide individual unit certification.

- Products produced in mass quantities can also obtain ABS Type approval to support an efficient product certification process.

The Type approval process verifies design and assessments in the manufacturing process to confirm whether a product or equipment meets industry standards and classifications.

PDA (Product Design Assessment) certificates are given to products that comply with manufacturing specifications, ABS rules, and national or international standards. The PDA certificate is valid for five years unless changes to the product are made.

- Other approval and certification categories include:

- Material manufacturers

- Service suppliers

- EU marine equipment directive

- Container certification services

- Periodic container inspection

- EN 10204 type 3.2 certification

- Welding and NDE testing

- Independent Lab for USCG

- Statement of compliance

What is the importance of having an ABS certification?

The importance of having an ABS (American Bureau of Shipping) certification is to ensure that companies producing vessels, products, materials, or equipment for the marine industry meet a global standard to ensure the safety and quality of vessels out at sea.

For products and materials to meet ABS standards and rules, they must go through audits and inspections. These audits and inspections are completed by committees of the ABS, which include maritime professionals like architects, steel makers, engineers (specialized in the marine industry), and shipbuilders. An ABS audit roughly consists of,

- Manufacturing assessment

- A physical or remote audit and inspection of the manufacturing facility are completed to ensure strict requirements are met.

- Product assessment (PDA)

- This review is one of the most critical steps in the classification process; drawings and documents are reviewed to make sure they comply with ABS standards.

- Certification is issued

- ABS certification ensures that materials and parts are created to meet a global safety standard.

- Companies that work with the American Bureau of Shipping suppliers may be able to minimize costs and inspection time.

- ABS-certified products can be used on vessels where governments require certain vessels to enter their country to meet certain certification standards.

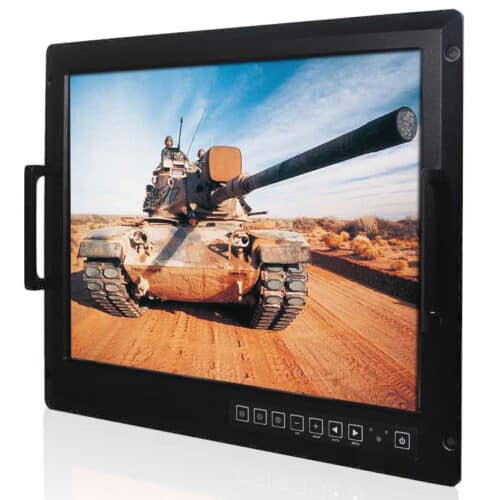

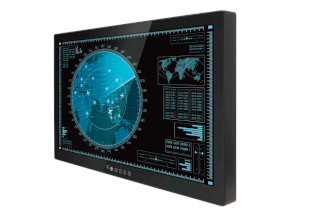

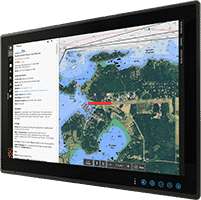

Sunlight Readable Touchscreen (SRT) & Pilot House Touchscreen (PHT) Displays – Now ABS certified

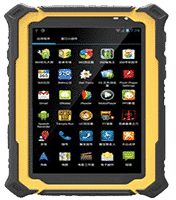

The Seatronx SRT/PHT marine industrial display offers rugged durability and a sleek look specifically designed for the marine environment.

This seatronx display is built for marine application and certified for the marine market. The SRT/PHT display is certified with ABS product design assessment (Type Approval), meaning that the display meets ABS standards and can be installed on any ABS-certified vessel. The display can also be installed on vessels not considered ABS-class vessels.

Apart from ABS certification, the SRT/PHT series display is also IEC60945 certified; this standard specifies minimum performance requirements and required test results for maritime navigation and radio communications.

The SRT/PHT series display features:

- A cost-effective glass bridge display that is sunlight readable up to 1500 nits

- The display also allows for a wide dimming range; dimming range is critical for nighttime viewing and safety

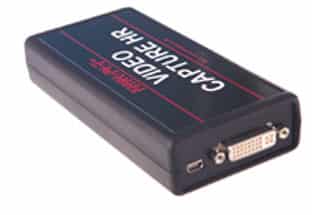

- NEMA 4, IP65 sealed front panel, this series also allows for multiple input options like HDMI, DVI-D, VGA & Composite video input

- The display itself allows for front brightness controls standard PCAP touch screen.

- HDCP compliant

- Has low power LED backlighting,

- It is great for vessels of all sizes as displays range from 12″ to 27″.